PPGI DC01

Classification :

PPGI Coil

Keywords:

PPGI Coil

E-mail: lynn@xhsteelcn.com

WhatsApp: +86 18353200241

PRODUCT DETAILS

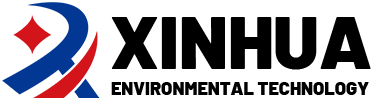

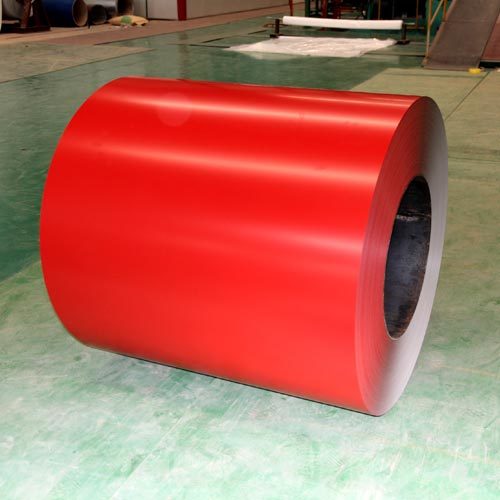

Color coated coil product introduction

The hot-dip galvanized sheet and zinc-iron alloy hot-dip galvanized sheet are used as the substrate, and after surface pretreatment, one or more layers of liquid coating are applied by roller coating, and then baked and cooled. The coatings used include polyester, silicon-modified polyester, high-durability polyester, polyvinylidene fluoride, epoxy and high-corrosion-resistant coatings, which have strong durability, corrosion resistance and formability. They are widely used in construction, transportation, home appliances, solar energy, furniture and other industries. The home appliance industry is mainly used for the production of refrigerators, air conditioners, freezers, washing machines and other shells.

Supply Range and Capacity

|

Project |

Color coating unit |

|

Unit type |

Two coatings and two bakings |

|

Substrate type |

Hot-dip galvanizing, aluminum-zinc plating, zinc-iron alloy |

|

Maximum process speed (m/min) |

120 |

|

Thickness (mm ) |

0.15-1.2 |

|

Width (mm) |

800-1250 |

|

Inner diameter of steel coil (mm) |

508/610 |

|

Maximum coil weight (tons) |

10 |

|

Coating type |

Epoxy, polyester, polyurethane, silicon-modified polyester, high weather-resistant polyester, polyvinylidene fluoride, cold-coated protective film, |

|

Production capacity (10,000 tons/year) |

24 |

Available grades and standards

|

Purpose |

Grade |

Implementation standard |

Purpose and characteristics |

|

General steel |

TDC51D+Z (ZF) |

GB/T 12754-2006 |

General construction |

|

Stamping steel |

TDC52D+Z (ZF) |

Material for mechanical occlusion and deep drawing, alloyed hot-dip galvanizing has better coating resistance and welding performance |

|

|

TDC53D+Z (ZF) |

|||

|

TDC54D+Z (ZF) |

|||

|

Structural steel |

TS250GD+Z (ZF) |

Can be used for structure, good corrosion resistance and processing performance |

|

|

TS280GD+Z (ZF) |

|||

|

TS320GD+Z (ZF) |

|||

|

TS350GD+Z (ZF) |

|||

|

TS550GD+Z (ZF) |

Application Areas

The color coated steel strip using hot-dip galvanized steel strip as the base material is protected by the zinc layer. The organic coating on the zinc layer plays a covering and protective role to prevent the steel strip from rusting. The service life is longer than that of galvanized strip, about 1.5 times. Color coated coils are light, beautiful and have good corrosion resistance. They can be processed directly. The colors are generally divided into gray, sea blue and brick red. They are mainly used in advertising, construction, home appliances, electrical appliances, furniture and transportation. The coating used for color coated coils selects appropriate resins according to different use environments, such as polyester silicon modified polyester, polyvinyl chloride plastisol, polyvinylidene chloride, etc. Users can choose according to the purpose.

Packing and delivery

The company is a comprehensive steel production and supplier based in China and serving the world, providing domestic and foreign buyers with a full range of services including production, procurement, marketing, processing, logistics, and information.

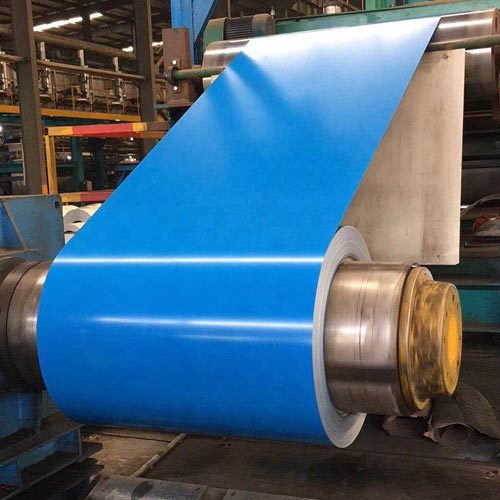

FACTORY APPEARANCE

The company's product manufacturing process chain is complete, relying on high-quality hot-rolled coils. Its main products are high-precision high-quality cold-rolled thin plates, galvanized thin plates, and color-coated thin plates.

APPLICATION AREAS

The products are widely used in high-end construction, home appliances, automobiles, light industry, hardware and other fields.

RELATED PRODUCTS

GET A FREE QUOTE